Products / Fluorocarbon Bulk Storage Systems

Fluorocarbon Bulk Storage Systems (R-22, R-134a):

What is a fluorocarbon bulk storage system?

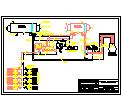

A Piedmont Energy Systems fluorocarbon bulk storage system is an integral unit of components designed, built and ASME certified to meet your specifications. It is delivered onsite ready to install and operate. The essential components of a fluorocarbon bulk storage system are:

The storage tank:

(we provide in a comprehensive range of capacities, sizes and ratings)

The pumps:

(which are side-channel centrifugal types mated to electric motors, all sized for your specific application)

The electrical components:

(typically consisting of the motor starters, control paneals and electronic sensors)

The regulating components:

(typically consisting of valves, gauges, level indicators, thermometers and filters)

R-22 bulk storage system installed in Thailand.

The Storage Tank.

Piedmont Energy System’s fluorocarbon bulk storage tanks are designed, fabricated, pre-tested and certified to meet all rigorous standards of the ASME section VIII, div. 1 Unfired Pressure Vessel Code. The storage tanks, pumps and othercomponents, are thoroughly cleaned, primed, and painted to completely protect the finish of your storage system from chemicals, weather conditions, ambient industrial factors, chipping and oxidation. The storage tanks have integral structural steel support systems with lifting lugs (commonly referred to as a “skid”) to facilitate shipping ease of loading/unloading. Each tank’s interior is open to maintenance and inspection via a bolted manway. Tank sizes and capacities are standardized to meet virtually every commercial and industrial need, but your custom requirements are easily accommodated at Piedmont Energy Systems, Inc.

The Pumps.

We take many factors into consideration when designing pumps to your needs. While two-pump systems allow you to overcome maintenance or emergency shut-downs, your fluorocarbon discharge requirements might make a single pump system adequate. The motors for your pumps are selected specifically to conform to your plant power requirements and your individual output system parameters. System valves permit you to service or replace any pump components without emptying your storage tank. We specify welded pipe in our pump systems which are rated in excess of 1000 PSIG and are of the highest quality carbon steel.

Electrical & Regulating Components.

All the gauges, regulators, level indicators, motor starters, switches, wiring, receptacles, thermometers, valves, and filters comprise this element of your fluorocarbon system. Safety valves prevent excess tank pressure and product flow is readily monitored at the loading line and liquid fill and vapor outlets. Gauges monitor tank and pump output pressure, liquid level (fixed remaining level indicators and float level indicators) and fluorocarbon temperature from -40°F to +160°F.

What sorts of distribution systems can Piedmont Energy Systems design and build?

Piedmont Energy Systems can design, fabricate and install any type of distribution system you might need. This turn-key service allows you to know the entire fixed cost of your new system. It can include everything from subcontracting concrete slabs and fencing to running distribution and manifold piping inside your plant. Our expert engineers can custom taylor your system depending on your current needs, future growth potential and key features you may want included. Typically, this sort of project will involve one of our engineers visiting with you and reviewing your needs and assessing your existing facilities or plans. Total project management from concept to commissioning is focused on customer satisfaction.